Quotation of GH990 High Speed Paper Cup Machine

-

Description

- Description:

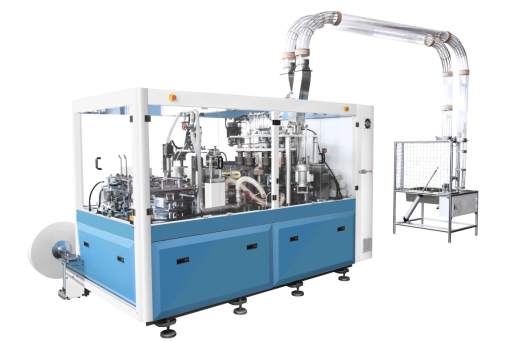

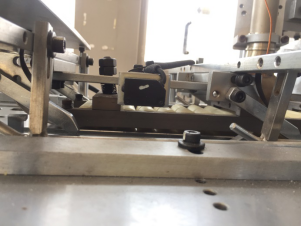

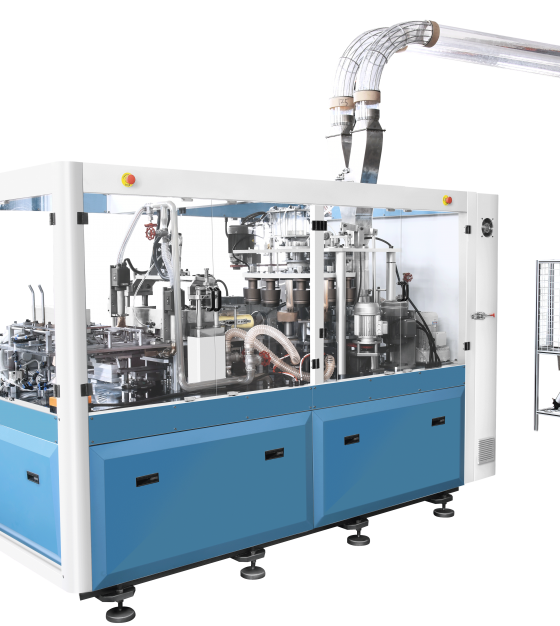

Our newly designed GH990 paper cup forming machine is a fully automatic paper cup forming machine, which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by robot hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre-heating, bottom knurling, cup discharging. The machine, researched and developed by our company, is improved steadily after comprehensive technical improvements.

- Main Features:

- Bottom sealing by hot air devices, so that the machine is efficient, the hot air device is imported from Switzerland.

- And cup side sealing by ultrasonic.

- More efficient and higher performance.

- Cup top curling and bottom knurling are finished by separate turn-plates.

- It is easy to make cups with different sizes by changing moulds.

- With automatic cup delivery system with counter.

First Quality, Best Service. We provide not only the products, but also the SOLUTION.

Quotation of GH990 High Speed Paper Cup Machine

Remarks:

| Price Item: | FOB Ningbo port, China. | |||

| Payment

Item: |

Option 1, T/T payment (30% deposit, 70% before delivery).

Option 2, Irrevocable L/C at sight (If pay by L/C, Extra $1000 bank charge per shipment). **** The buy is welcomed to test machine before delivery. |

|||

| Delivery Time: | 40~60 days at sight the deposit. (actual delivery time given while order confirm) | |||

| Package: | Standard export package. (need special package, please info us in advance). | |||

| Electric Power Source: | The electric power source for this machine adopt 380V 3-phase 50Hz.

If the buyer’s power source different, should declare in advance. |

|||

| After Sales Service: | ||||

| 1 | We offer a 12 months warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems (post charges covered by buyer). All failures/breaking caused by improper operation of the buyer and/or normal abrasion are not within the warranty. | |||

| 2 | Spare Parts: Each machine has its standard spare parts (see list). | |||

| 3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). | |||

| 4 | The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free.

(buyer should pay for his cost of ticket, hotel, food, etc). |

|||

| 5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer.

Technician cost includes: round tickets, accommodation (hotel, food), an allowance of USD100 per day. |

|||

ZBJ- GH990 High Speed Paper Cup Machine

- Description:

Our newly designed GH990 paper cup forming machine is a fully automatic paper cup forming machine, which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by robot hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre-heating, bottom knurling, cup discharging. The machine, researched and developed by our company, is improved steadily after comprehensive technical improvements.

- Main Features:

- Bottom sealing by hot air devices, so that the machine is efficient, the hot air device is imported from Switzerland.

- And cup side sealing by ultrasonic.

- More efficient and higher performance.

- Cup top curling and bottom knurling are finished by separate turn-plates.

- It is easy to make cups with different sizes by changing moulds.

- With automatic cup delivery system with counter.

Running Machine Video Link: https://youtu.be/FaNU75wgNqM

- Technical Parameter:

| Model | GH990 |

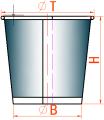

| Cup Size | 3oz ~42oz |

| Raw material | 190~350gsm Single or Double PE coating paper |

| Output | 120~150pcs/ minute(Cup); 90~110pcs/min(Bowl) |

| Electrical requirement | 380V, 3-phase |

| Working Power | 18KW |

| Air Specification | 0.5~0.8Mpa, 0.4m^3/min |

| Configure Power | 21KW |

| Packing dimensions | L2900mm×W1380mm×H1800mm |

| Machine Weight | 5000 kgs |

| Cup Use | round paper cups, drinking , noodle and vending cups ice-cream and food containers |

- Leading Technology:

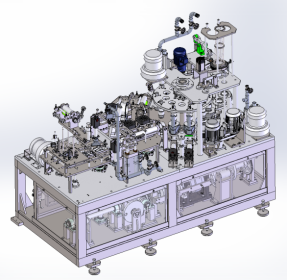

- Adopts rotation type paper feeding type instead ofprevious pendulum type paper feeding type:

Advantage:

(1). Prevent dust and wastepaper from entering the lubrication system;

(2). The rotation is more stable while the pendulum is too long and easy to shake.

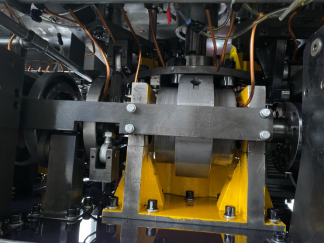

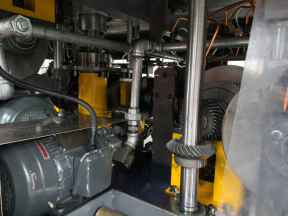

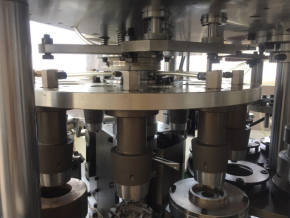

- Box type open cam drive system with double longitudinal axis, all cams adopt 20CrMnTi numerical control (Nc)machining to do precision grinding.

- Continuous Automatic Spray Lubrication.

- Full-gear drive.

- Integrated rack design

1, Output is improved: The productivity is improved from 100~120 pcs/min to 130-150 pcs/min.

- Some Improvements:

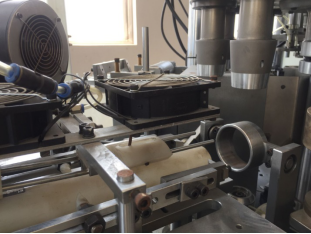

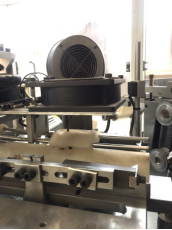

Machine has fours fans help heat dissipation when machine working in high speed.

Four hot air devices.

1.Two for cup fan sealing(Improvement on G12, better sealing effect)

2.Two hot air devices for bottom sealing. (Improvement on G12, better sealing effect

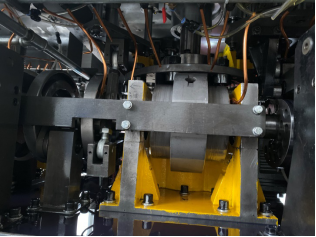

10 divide open cam+10 sets of molds; 7 divide open cam+7 sets of molds(cup top curling mold):

- Main Parts Brand List:

- Workshop:

- Sample Display:

10.Company:

- Certificate of our machine

Machine Video

Machine Video