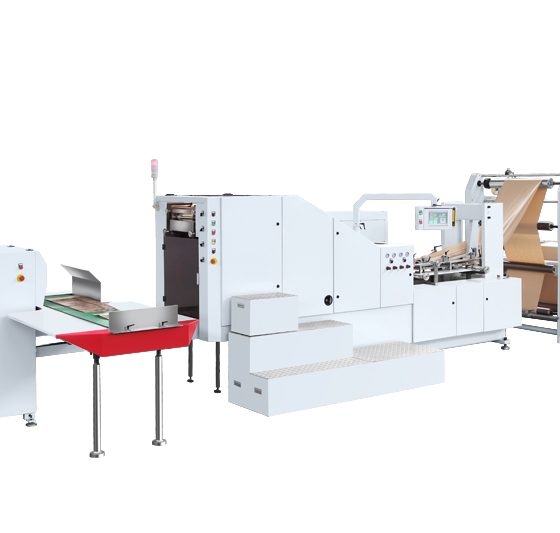

Quotation of QCFD-330 Fully Automatic High Speed Square Bottom Paper Bag Making Machine (Patch Bag)

-

Description

- purchased parts used in this machine will be replaced by the same-level brand that is not lower than the existing brand quality when the equipment is upgraded or updated. The seller will reserve the right without further notice.

- Description:

Roll-fed square bottom paper bag making machine, uses paper roll in blank or printed as raw material. The process consists of automatic centre sealing, printed bag tracking, fixed-length cutting, bottom creasing, bottom folding, and bottom sealing. Bag bottom forming and bag collecting are completed at one time.The machine, more convenient, more efficient and stabler, can produce a variety of different eco-friendly paper bags for food, bread, dried fruit packaging.

- Main Features:

1.Use France SCHNEIDER touch screen human-computer interface, making the machine easy to operate and control.

2.Adopt Germany original REXROTH PC control, integrated with optical fiber. Thus ensure stable and high speed running.

3.Adopt Germany original REXROTH servo motor and German original SICK photoelectric eye correction, tracking printing bag accurately.

4.Patch bag function adopts a complete set of German original Rexroth servo motor. Through integration with optical fiber, it works with the German original Rexroth motion controller (PC).

5.Automatic hole-punching adopts Germany original Rexroth servo motor.

6.Raw material loading adopts hydraulic auto-lifting structure. Unwind unit adopts auto tension control.

7.Raw material unwinding EPC adopts Italy SELECTRA, reducing material alignment time.

Date: 11th, June, 2019 Validity:30days

| Description | Unit Price(USD) | |

| QCFD-330 AUTOMATIC HIGH SPEED SQUARE BOTTOM PAPER BAG MACHINE(Patch Bag) | FOB 103,000USD Ningbo | |

| Patch Bag | FOB 72,000USD Ningbo | |

| PAYMENT TERM | After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok. | |

| Delivery time

|

About 90 working days after receiving the deposit. The factory will decide whether to change the delivery date when the order is confirmed. | |

| Electrical equipment | This machine adopts three-phase 380v. If you have any special requirements, please explain in advance with my company. | |

| Guarantee | We offer a 12-month warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures caused by improper use of the buyer (including unauthorized modification of PC and touch screen built-in software) are not within the scope of the warranty (except for the vulnerable parts of wearing parts). | |

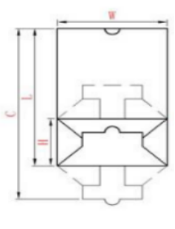

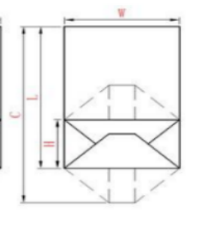

3.Sample Display:

4.Technical Parameter

style=”height: 990px;” width=”656″>

- Main Electrical Components List

| Name | QTY | Original | Brand |

| Control System | |||

| PC Program Controller | 1 | Germany | REXROTH |

| Human-computer touch screen interface | 1 | France | SCHNEIDER |

| Servo Motor | 1 | Germany | REXROTH |

| Servo driver | 1 | Germany | REXROTH |

| Master encoder | 1 | Germany | REXROTH |

| Main traction motor | 1 | Taiwan | DELTA |

| Main traction servo driver | 1 | Taiwan | DELTA |

| Servo motor for bag counting | 1 | Taiwan | DELTA |

| Servo driver for bag counting | 1 | Taiwan | DELTA |

| Bag forming motor | 1 | Taiwan | |

| Bag forming frequency converter | 1 | Switzerland | ABB |

| Photoelectric eye for printed-bag tracking | 1 | Germany | SICK |

| Optical fiber communication separator | 1 | USA | |

| Low voltage electrical apparatus | 1 | France | SCHNEIDER |

| Photoelectric sensor | 1 | USA | BAUMER |

| Pneumatic component | 1 | Taiwan | |

| Auto lubricating | 1 | China | |

| Air conditioner for electric control box | 1 | China | |

| Name | QTY | Original | Brand |

| Patch handle control | |||

| Servo Motor for cutting | 2 | Germany | REXROTH |

| Servo driver for cutting | 2 | Germany | REXROTH |

| Servo motor for patching position | 2 | Germany | REXROTH |

| Servo driver for patching position | 2 | Germany | REXROTH |

| Servo motor for gluing position | 2 | Germany | REXROTH |

| Servo driver for gluing position | 2 | Germany | REXROTH |

| Servo motor for hole-punching position | 1 | Germany | REXROTH |

| Servo driver for hole-punching position | 1 | Germany | REXROTH |

| Name | QTY | Original | Brand |

| Deviation correction and tension control system | |||

| EPC controller | 1 | Italy | SELECTRA |

| Servo motor for EPC | 1 | Italy | SELECTRA |

| Ultrasonic sensor | 1 | Italy | SELECTRA |

| Magnetic powder brake | 1 | China | WEIZHENG |

| Name | Qty | Original | MTED |

| Transmission | |||

| Synchronous belt | 1 | China | BELDI |

| Synchronous wheel | 1 | China | MTED |

| Bearing | 1 | Germany | FALA |

| Guide roller | 1 | China | BAIXIAO |

| Gear | 1 | China | MTED |

| Air shaft for paper roll | 1 | China | MTED |

| Name | Qty | Original | MTED |

| Glue position | |||

| Bottom glue (bottom-sealing white latex) | 1 | China | MTED |

| Motor for bottom glue evening | 1 | China | |

| Pneumatic auto glue filling valve | 1 | China | |

| Spraying gun for center sealing (dense adjust Glue gun ) | 1 | China | XLG |

| High-pressure glue barrel for white latex | 1 | China | MTED |

Remarks:

The purchased parts used in this machine will be replaced by the same-level brand that is not lower than the existing brand quality when the equipment is upgraded or updated. The seller will reserve the right without further notice.

Machine Video

Machine Video