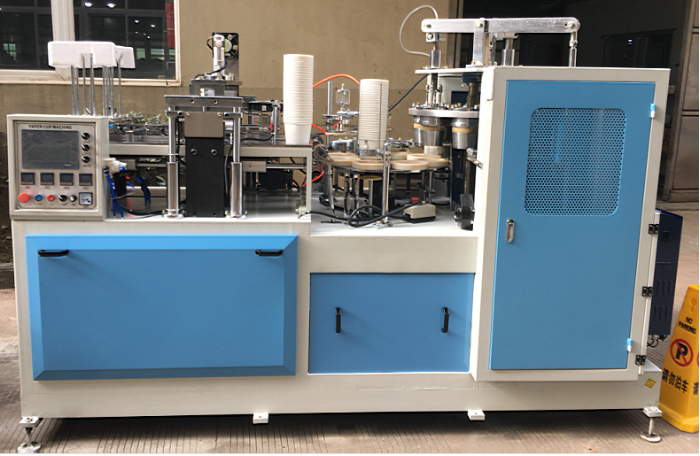

ZBJ-X35 Ultrasonic Paper Bowl Machine

-

Description

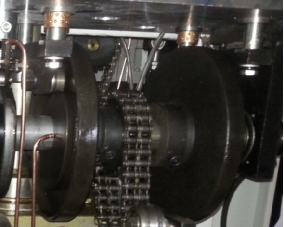

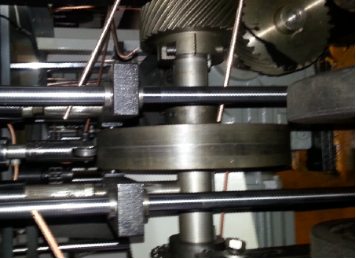

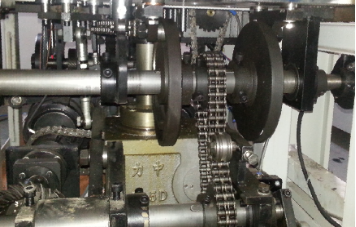

1, Gears & Axis control movement, two index gear box, more efficient & accurate.

2, HMI & PLC Program computer control, easy operate, fault auto-stop and easy solution.

3, All procedure sensor detect (11-sensor control all step), Less wastage & fault, Reliable.

4, Self lubrication (Automatic Oil Lubrication for machine moving part), long life time.

5, Import electric Elements, Superior Bearing & Quality material, more durable and reliable.

6, Working power only 3.5KWH, save electric power cost.

7, One worker can run 2sets machine (machine assemble cup stock), save labor cost.

8, Main gear box is 140#, Bottom punching gear is 80# (two gear box).

9, Speed improved from 30 pcs/m to 50~60 pcs/minute.

| HS Code: | 8441309000 |

| Name: | ZBJ-X35 Ultrasonic Paper Bowl Machine |

| FOB Price | $18,000/set (include one set of user mold ) |

| Extra Turn Collector | $1,200/set (for bowl collector is turn collection/stacker), |

| Extra Half Set Mold | $800 (Half Set Mold, Cup Bottom Same AND Cup-Angle Same) |

| Extra Whole Set Mold | $1,600 (whole set mold, Cup Bottom different, or Cup-Angle different) |

| Model | ZBJ-X35 |

| Rated Speed: | 40~60 PCS/minute, (3000~3600 PCS/hour, on cup size, paper quality and thickness) |

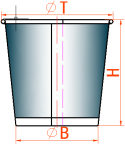

| Paper Cup Size: | 20~50 oz (mold exchangeable) |

| Raw Material: | One or Two side PE film coated paper, |

| Suitable paper weight: | 170~450 gsm |

| Power Source: | 380V 3-phase, 50HZ |

| Total Power: | 8KW |

| Working Power: | 3.5KWH |

| Total Weight: | GW/NW: 2700/2500 KG |

| Pack Size (L*W*H) | 2900 x 1450 x 2000 mm |

| Working Air Source: | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute

User should BUY Air Compressor |

| Cup Side Welding: | Ultrasonic System |

| Cup Bottom Heating: | Hot air (need air compressor to supply air) |

| Cup Bottom Knurling: | Heater Knurling (if use single PE coated paper) |

| Cool Device (recycle water) knurling, for double PE coated paper |

Remarks:

| Price Item: | FOB Ningbo port, China. | |||

| Payment

Item: |

Option 1, T/T payment (30% deposit, 70% before delivery).

Option 2, Irrevocable L/C at sight (If pay by L/C, Extra $1000 bank charge per shipment). **** The buy is welcomed to test machine before delivery. |

|||

| Delivery Time: | 30~60 days at sight the deposit. (actual delivery time given while order confirm) | |||

| Package: | Standard export package. (need special package, please info us in advance). | |||

| Electric Power Source: | The electric power source for this machine adopt 380V 3-phase 50Hz.

If the buyer’s power source different, should declare in advance. |

|||

| After Sales Service: | ||||

| 1 | We offer a 12 months warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures/breaking caused by improper operation of the buyer and/or normal abrasion are not within the warranty. | |||

| 2 | Spare Parts: Each machine has its standard spare parts (see list). | |||

| 3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). | |||

| 4 | The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free.

(buyer should pay for his cost of ticket, hotel, food, etc). |

|||

| 5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer.

Technician cost includes: round tickets, accommodation (hotel, food), an allowance of USD100 a day. |

|||

Description:

ZBJ-X35 ultrasonic paper bowl machine is designed for big size bowl/cup.

Advanced:

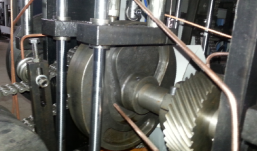

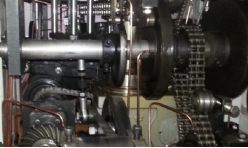

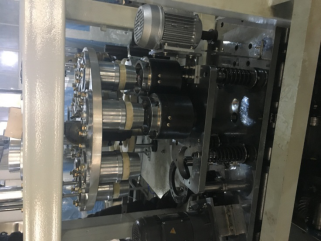

1, Gears & Axis control movement, two index gear box, more efficient & accurate.

2, HMI & PLC Program computer control, easy operate, fault auto-stop and easy solution.

3, All procedure sensor detect (11-sensor control all step), Less wastage & fault, Reliable.

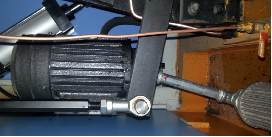

4, Self lubrication (Automatic Oil Lubrication for machine moving part), long life time.

5, Import electric Elements, Superior Bearing & Quality material, more durable and reliable.

6, Working power only 3.5KWH, save electric power cost.

7, One worker can run 2sets machine (machine assemble cup stock), save labor cost.

8, Main gear box is 140#, Bottom punching gear is 80# (two gear box).

9, Speed improved from 30 pcs/m to 50~60 pcs/minute.

|

PLC program control system, Intelligent control the movement, easy operate and maintenance, Keep the machine runs smoothly, less fault and less wastage. |

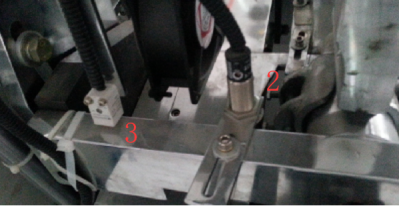

Adopt 11 sensor detecting all the step, with CPU program control, fault solution.

This device adopt non-contact multi-point light control switch. It can detect all the working situation, control all the moving steps, keep the machine more stable and reliable. With the function of fault alarm, stop, and solution, easy operating.

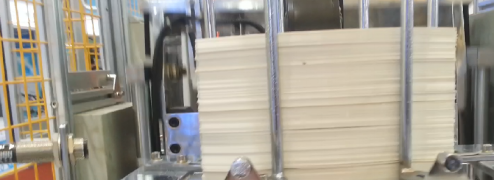

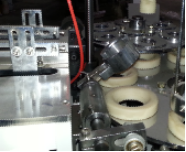

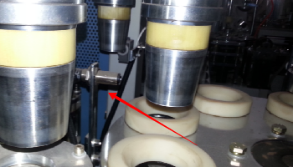

| Four PCS QUALITY suck rubber & Blower separate blank, More accurate . | |

|

|

|

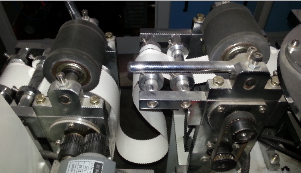

Three steps long guide, Accurate for cup blanks. |

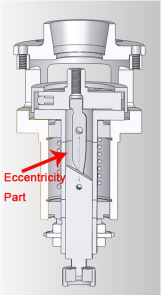

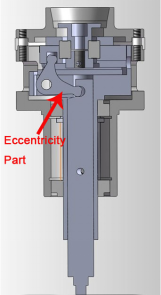

Inside cam control the cup body sealing, More accurate and no noise. |

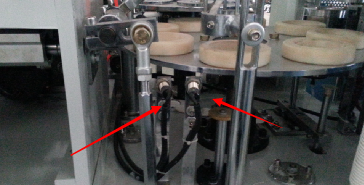

Stepping-motor control the bottom-reel paper feeding, which keep the bottom-disk gap within 0.1mm (more stable and save paper). Program keep the cup-bottom-feed corresponding to its cup-cone-body, the machine will be stopped when out of bottom-paper, avoiding the waste in paper.

Servo Motor feed cup bottom disc, one cup blank one bottom disc, no waste.

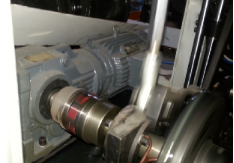

Two steps feeding more accurate. Bottom reel feed motor

Adopt high quality material for knurling device, and improved reliable knurling system, keep the bottom knurling more better, and no leakage, long life time, easy run.

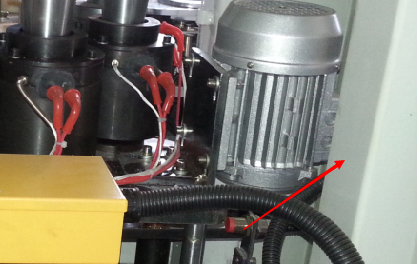

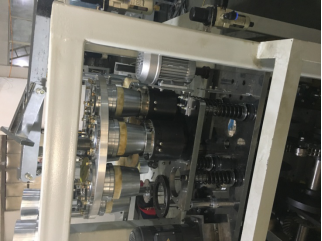

Reduce-motor keep the motor efficient. Simplified the trans simplifies the transmission system and keep the machine more stable |

Self-Lubrication Motor & Pump Automatic oil lubrication. |

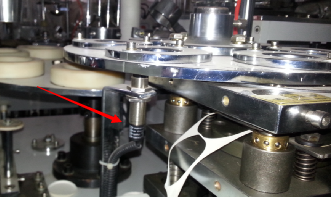

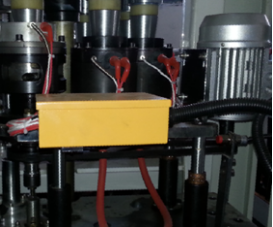

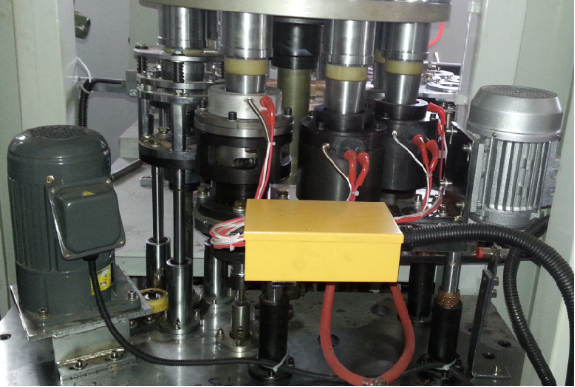

Cup bottom up/down board improvement: Bottom knurling & Top Curling adopt separately motor, keep the machine fast speed, knurling and curling more stable and reliable,

| Cup bottom up/down board improvement: adopt separately cam control the knurling & curling.

The up/down board become light, more accurate, Knurling & curling better. |

|

Curling Control |

Knurling Control |

Separately cup/down board, to light the movement pressure, Less moment, Fast & Stable.

| ZBJ-X35

NEW Improvement

Bottom heating, knurling in one up/down board.

Top curling separately move up/down

|

|

| Old model

Bottom heating, knurling, top curling all in one up/down board. |

|

| Separately CAM control bottom knurling press, keep the bottom sealing better, Easy adjustment. |

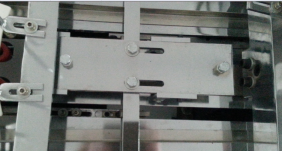

Machine frame material better. Total machine weight 2650KG, heavier than old model 1300KG.

Frame adopt SQUARE STEEEL PIPE instead of U-steel & angle-steel,

Machine top and bottom adopt 12mm steel board.

Improved frame design, machine moving parts almost covered and dust prevented, keep the moving parts and system long life time.

ZBJ-X35 ZBJ-X35 |

|

| Quality Gears, Axis, Cam, Bearing, more accurate, keep stable & reliable, Durable. | |

|

|

Dd

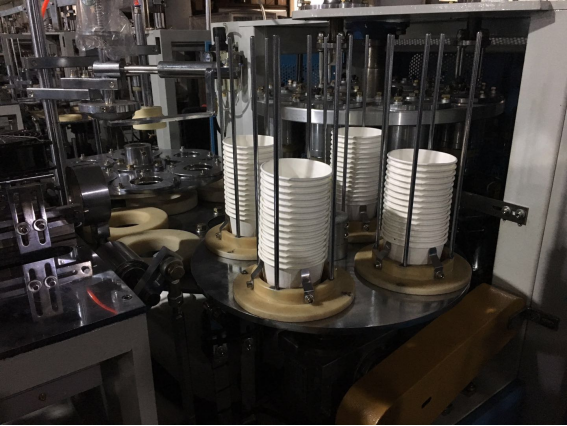

Paper bowl is big size, so shoot bowl sometimes not available,

To help collect the bowl, turn collector/stacker is an option.

Running Machine Video Link: https://www.youtube.com/watch?v=5jTug5v5uX0

Paper bowl machine with turn collector/stacker

Turn collector/stacker (option) (Extra USD1200/collector)

Available to make paper noodl box, french fries box

Machine Video

Machine Video